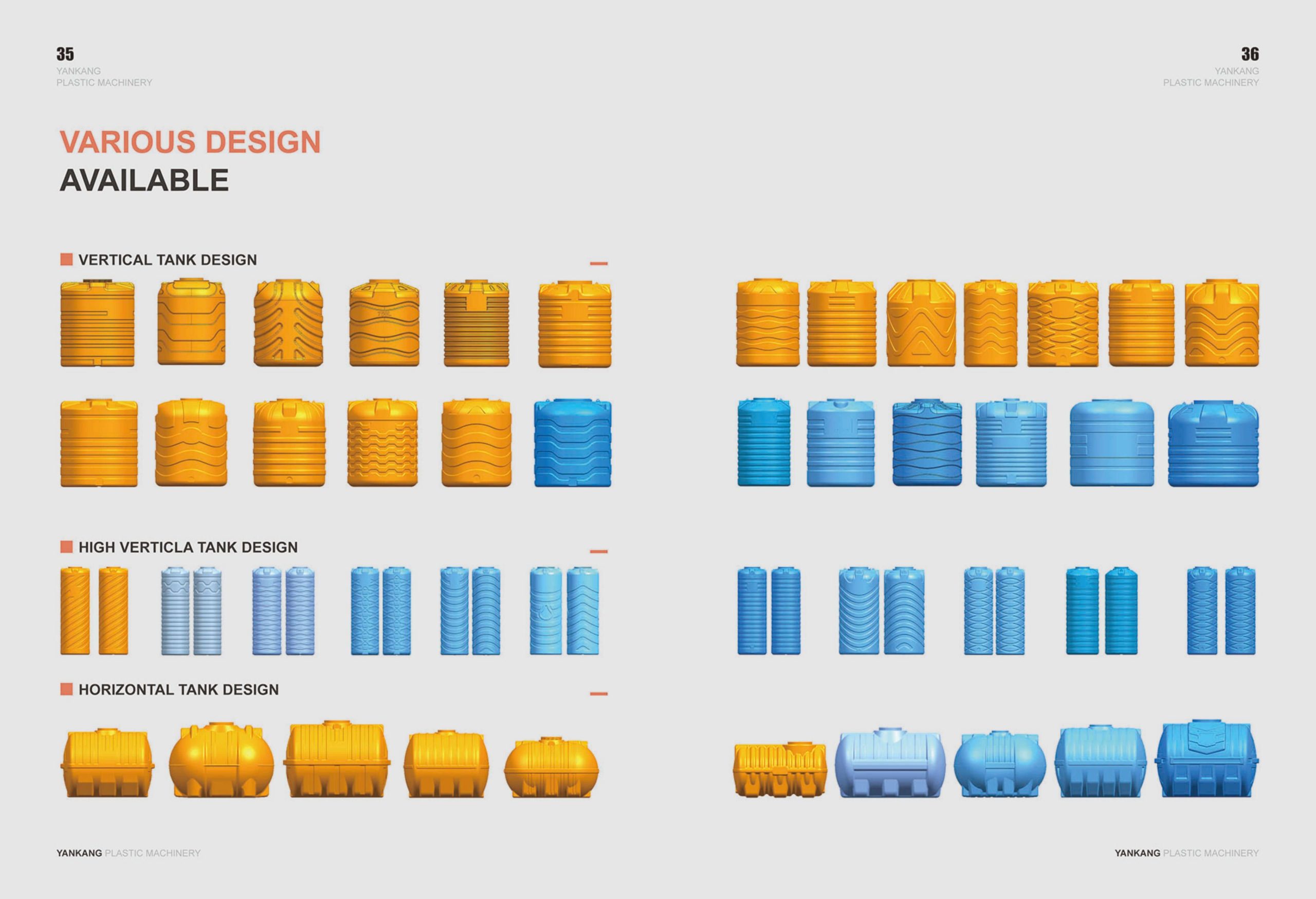

There’s a whole bunch of different types of plastic water tanks out there, each with its own set of features, and let me tell you, designing a good plastic water tank ain’t no walk in the park.

(1) General Principles of Plastic Water Tank Design

When it comes to designing plastic water tanks, you gotta start with the intended use. Here are some key principles to keep in mind:

① Make the most of the mechanical properties of plastic while avoiding or compensating for its shortcomings. You really need to think about the strength, rigidity, toughness, elasticity, and how sensitive it is to stress—those mechanical characteristics are crucial.

② The moldability of plastic and the impact of the molding process on the design of the water tank are vital. You gotta consider the flow characteristics, crystallinity, shrinkage, thermal stability, curing properties, and molecular orientation.

③ After the water tank is molded, you need to pay attention to how it shrinks and the differences in shrinkage rates that could lead to warping or deformation.

④ The shape of the plastic water tanks should not only meet the usage requirements but also facilitate the molding process. Plus, it should be able to handle efficient cooling for thermoplastics or quick curing for thermosetting plastics.

⑤ Lastly, the design of the plastic water tank should take into account the overall structure of the molding tools. Keep the mold design as simple as possible, while also considering the shape of the mold parts and their manufacturing processes to ensure the final product is cost-effective.

(2) The main content of the innovative design of plastic water drums includes three major aspects:

1. Functional Structure Design

The functional structure design is the core of the plastic water barrel design, encompassing elements related to the tank’s functionality, such as shape, size, precision, surface roughness, threads, and holes.

2. Process Structure Design

From the perspective of plastic molding and processing technology, the design of plastic water barrels should consider process factors including wall thickness, draft angles, ribs, support surfaces, and radii.

3. Shape Structure Design

The primary content of the structural design of plastic water tanks includes the shape, size, precision, surface roughness, wall thickness, slope, ribs, support surfaces, radii, threads, holes, inserts, as well as surface text, trademarks, and patterns on the container.

These are some of the key elements and fundamental principles regarding the design of plastic water tanks. As a professional manufacturer of plastic water tank blow molding machines, Yankang possesses extensive experience and practical knowledge in the research and design of plastic tank machinery.

Contact Yankang to learn more about the relevant information and pricing for plastic water tank manufacturing machines.